Cooking and preparing food is a great deal easier if you have a good knife. I spent years struggling with inherited blunt junk shop knives. My mother doesn’t have a good knife, nor does my sister, my sister-in-law or my niece, and they are all keen cooks. Having a good knife doesn’t appear to be a female objective when it comes to kitchen tools. For male cooks it’s probably the first thing they would buy.

For Christmas I gave my niece a Global knife:

‘It’s changed my life’ she enthused.

This summer, at my parents kitchen at their home in France, frustrated with the hand-me-down knives from previous occupants, I nipped out to the local supermarket and bought my mum a couple of knives: an all-purpose Chefs and a small ceramic paring knife.

‘It’s changed my life’ said my mum.

Earlier this year I visited Blenheim Forge in Peckham, which makes hand-forged knives. It was started by three self-taught friends in their late twenties: Richard Warner, Jon Warshawsky and James Ross-Harris. They met when they were students house sharing. Richard and James studied design engineering at Goldsmiths college while John did philosophy at Kings.

Their workshop is under Victorian brick railway arches. Outside, the forge spits and hisses.

‘Our steel starts off like bars. Which becomes the dark part of the knife. This is Japanese blue paper steel- ‘yasuki steel’ ordered from Japan.’

‘That’s just over £30, if that was ordinary steel… it would cost £2.’

‘One of the best. We make Japanese inspired knives so we use their steel.We make our knives using their hands-on process. German knives are really good, but factory-made. The Japanese style of making stuff is more human.’

‘There’s definitely heritage in Sheffield. Sheffield steel is famous. Stainless steel was invented in Sheffield.’

‘Sabatier, Opinel.’

‘You could do worse. They are not… they are mass produced. The grade of the steel isn’t high.’

‘Trial and error. We played around with it for a long time. There’s not many places you can learn to do what we do.’

‘We laminate the steel, fusing it together with other metals to create a sort of sandwich. We fold it many times depending on how many layers are needed. Some knives have 30 layers, some have 300 layers. Functionally there’s not a massive difference, it’s more a style. ‘

‘A laminated blade has many advantages over a single sheet of metal. Most (culinary) knives used to be laminated. It’s coming back into fashion. In the East, in Japan, 90% of the blades are laminated and have been for years but now this technique has been rediscovered in the West- first in the United States, reappearing thirty or forty years ago. It’s like puff pastry. You can see the difference, the middle layers, folded outside.’

‘Nigella has got a blade from us. Her publisher bought her one. Jay Rayner has got one. Frances Mallman, an Argentinian celebrity chef. But mostly we cater to anyone who likes to cook, not celebrity chefs. Most of our customers are home users.’

‘Our knives are a little bit more expensive than Global. Relatively they are cheaper… if you compare a Macdonalds hamburger to say Wagyu beef. Big Macs are expensive because it takes fuck all for them to make a hamburger. Same for mass-produced knives. You are paying for branding, marketing, transportation.’

‘Three years.’

‘It helps being three of us. Normally it would take say eight years by myself. It’s accelerated the learning curve. You could say we have nine years worth of experience between the three of us.’

‘Cut off the excess and you end up with a blade. This will then be heated, make it look like a blade, it’s a bit thick right now. Fifteen layers of iron folded on the outside. For our standard blades, the layers are more for looks, you don’t need an excessive number of layers. We just make a few on the outside, to give it support, so you don’t end up with a blade that’s too expensive. Every process takes longer when you do it by hand but we want an affordable high quality blade.’

‘It goes even lighter.’

‘It depends what blade you want to end up with. This style is Kyoto, which is stronger, meant for processing meat. Kyoto were created when they started importing western knives to Japan and they saw a western chef’s knife, longer and wider than a Japanese chef’s knife, which is a Santoku.’

I’ve got a Santoku, which has a kind of diagonal at the end.

‘A Kyoto is a Japanese interpretation of a French sabatier knife 100 years ago.’

‘Richard made a few.’

‘We make them from walnut, which has nice patterns on it. The bit at the end is copper.’

‘It looks nice and gives a bit more weight to the handle. Otherwise you end up with a pretty light handle. It balances out the weight. If you didn’t have any metal on the handle, you’d end up with a knife that tips forward.’

‘We like the things we are doing at the moment. We make between 20 and 30 knives a week.’

‘We have a lot of expenses but we make just enough to make a living. We could be making 50, but your quality goes down once you increase your numbers. The three of us make 10 knives each. Ten knives is manageable. You know each knife. If you make more it gets messy.’

‘You want them all to be different in some respects’.

‘The knives have got character. If you’ve forged it well, you get that wave where the black line touches the rim of the edge of the blade. If another blacksmith looks at it, it’s a gage for the level of skill. We still make a lot of mistakes, so we waste material.’

‘No.’

‘No. We used to but not anymore.’

‘If a knife was rejected, we’ve profiled it wrong. The finish is not good…’ Jon strokes a knife: ‘The handle and blade fit well on this one. It’ll be a bit of a step with your finger. You’ll have a little sharp corner in there. That seems like a detail but after using it for hours, you’ll notice.

‘Not really but I use my own knives at home.’

‘No they are being finished, oiled.’

‘No. There are ladies who like big knives and ladies who like…’ He laughs. ‘Probably men would like larger ones. Your hands are like different sizes, but food is the same size.’

‘Most knife making techniques are derived from making swords.’

Do you make axes? I had a boyfriend who was a lumberjack. He was a genius with an axe. The way he behaved with an axe- it was like an extension of his arm.

‘If you make axes you’ve got to make just axes. You have to specialise. We don’t do weaponry things. It’s a different mentality. Kitchen knives are finer products. We make small hunting knives but if you go into swords and machetes, you need a bigger set up, a bigger forge, a bigger grinder. At the moment we are set up to do small fine things.’

‘My dad used to cook quite a lot, he went to cooking school. I’m trying to do a more French style of knife. The shape is different, more classical. This shape is more European. The shapes are more simple.’

A Sabatier look?

‘Yes. They have a more triangular shape. For me, I love this shape. This is all-purpose. It’s quite small, if you cook with meat.’

‘…when they first started. Obviously they worked a lot to develop their skills and on the way… ‘ he shrugs.

‘They come in this cardboard sleeve with Blenheim Forge stamped on it. It’s simple but represents well the spirit of the brand. Efficient. It takes about 3 weeks to get one if you order.’

‘We are doing the hot work: the forging, the grinding, heat-shaping the blades, making the final blade shape that you want. You heat it up and cool it down really fast;

‘Start high – 800c then bit lower. Three times for most. Last time is on medium heat, to seal it.’

‘You want to achieve a result with the lowest temperature possible. The environment inside the forge, you keep it so that’s there’s almost no oxygen.The more it oxidises, you end up with less carbon content in the steel. So when you harden it, it’ll be less hard. The edge will not last as long.’

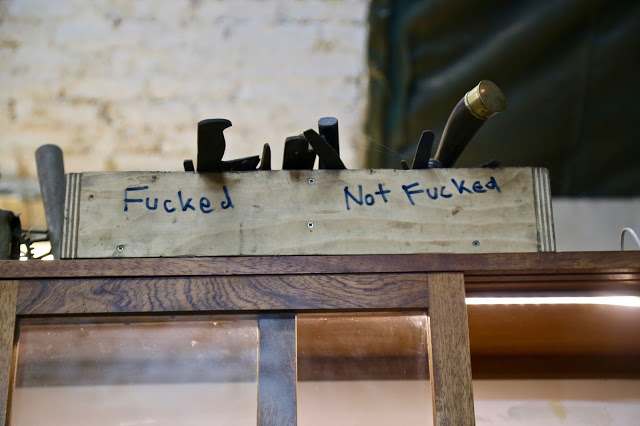

‘You can’t buy it. we made it. That’s why it looks so pikey’, Jon grins.

‘We lived in Peckham. Now it’s really expensive, unbelievable! Eight years ago when we first moved to Peckham, it was £200 a month for a really nice semi-detached house. Now you don’t find things under £700. It’s tripled. Even a workshop like this, the rent’s gone up.’

‘If we can. But all of this is coming down’ Jon gestures to the archways. ‘It could be five years, could be 15. Peckham’s kind of cool now.’

[…] a 10 year old will feel quite empowered by someone trusting him with a knife. Have you been to Blenheim Forge? I went there and did a piece on them. They’re making all different kinds of knives in a […]